Flame-retardant ABS has good mechanical strength, excellent flame-retardant properties and thermal stability, good fluidity, and convenient molding and processing.

¥ Negotiable

Flame retardant ABS characteristics:

Flame-retardant ABS has good mechanical strength, excellent flame-retardant properties and thermal stability, good fluidity, and convenient molding and processing.

use:

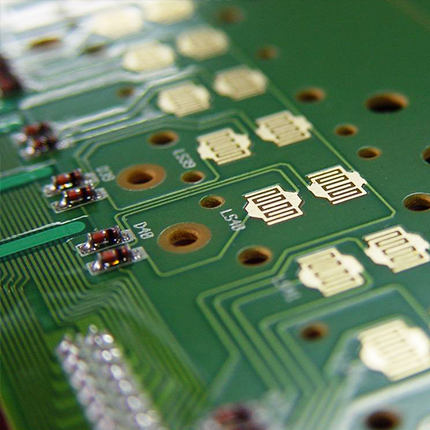

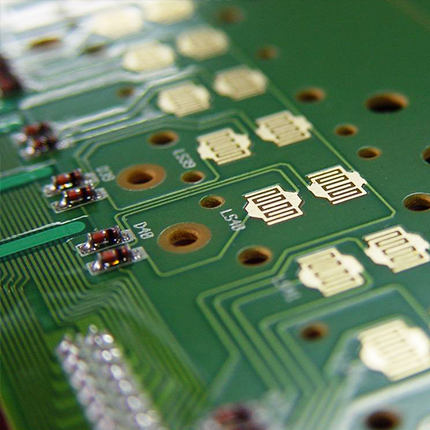

Flame-retardant ABS can be used to manufacture household appliances housings, office electrical housings, electrical housings, electrical switches, wiring boards, industrial and civilian electric watch cases, and electronic components.

processing method:

ABS modified materials for injection molding, the proposed processing temperature of 195-225 °C, mold temperature in the 40-80 °C, injection pressure 60-90MPa, drying temperature 80-85 °C, 2-3 hours.

Flame retardant ABS physical properties:

| Test items | unit | Test Methods ASTM | General flame retardant | Impact-resistant flame retardant | Environmental protection flame-retardant | Environmental protection flame-retardant |

| product name | FABS01 | FABS04 | FABSEF02 | FABSEF03 | ||

| Tensile Strength | Mpa | D638 | 40 | 210 | 42 | 38 |

| density | g/m3 | D972 | 1.2 | 1.16 | 1.18 | 1.16 |

| Elongation at break | % | D638 | 15 | 24 | 15 | 20 |

| Bending strength | Mpa | D790 | 65 | 60 | 62 | 60 |

| Flexural modulus | Mpa | D790 | 2250 | 2000 | 2200 | 1900 |

| Heat distortion temperature | ℃ | D648 | 83 | 80 | 82 | 80 |

| Notched impact strength | KJ/m2 | D256 | 12 | 18 | 11 | 16 |

| Melt finger | g/10min | D1238 | 50 | 60 | 40 | |

| Flame retardancy | U194V0 | V0 | V0 | V0 | V0 | |

| High light, weatherproof | Weatherable |

Note: The data reported above is not used as a specific technical specification. The basic test data is for reference only for the performance of this product.