characteristic:

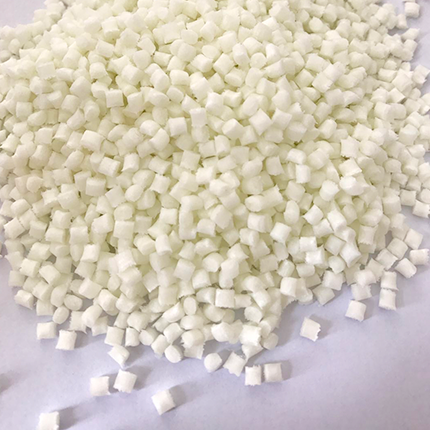

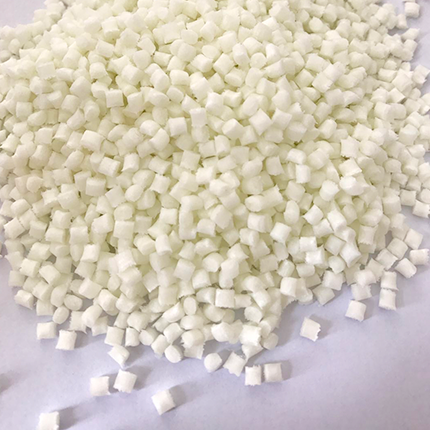

Enhanced PA6/PA66 has high mechanical strength, good heat resistance, dimensional stability, good electrical properties, easy processing and molding.

¥ Negotiable

characteristic:

Enhanced PA6/PA66 has high mechanical strength, good heat resistance, dimensional stability, good electrical properties, easy processing and molding.

typical application:

Enhanced PA6/PA66 can be used to manufacture automotive parts, sports equipment, communications equipment, electrical equipment parts, power tool housing and so on.

processing method:

Reinforced nylon is used for injection molding. The recommended processing temperature is 235-275°C, mold temperature 60-90°C, injection pressure 60-100MPa, and drying temperature 85-90°C for 6 hours.

Enhanced PA6, PA66 property table:

| Test items | unit | standard test | Test Conditions | B3GFR30 PA6-GF30 | B3GFR50 PA6-GF50 | A3GF30 PA66-GF30 | A3GF50 PA66-GF50 |

| product name | |||||||

| Tensile Strength | Mpa | ISO527-5 | 5mm/min | 170 | 195 | 170 | 200 |

| density | Mpa | ISO527-5 | 5mm/min | 10000 | 16000 | 10000 | 18000 |

| Elongation at break | % | ISO527-5 | 5mm/min | 3.5 | 2.5 | 2.5 | 2 |

| Bending strength | Mpa | ISO178 | 2mm/min | 220 | 260 | 230 | 280 |

| Flexural modulus | Mpa | ISO178 | 2mm/min | 7600 | 11000 | 7800 | 14000 |

| Non-notched impact strength | KJ/m2 | ISO179-1 | 23℃ | 80 | 80 | 60 | 80 |

| Notched impact strength | KJ/m2 | ISO179-1 | 23℃ | 12 | 14 | 10 | 9 |

| Melt finger | g/10min | GB3682 | 275℃,5kg | 8 | 18 | 18 | 14 |

| Fiberglass content | % | GB/T9345 | 30±3 | 50±5 | 30±3 | 50±5 | |

| Moisture | % | Business standard | |||||

Note: The data reported above is not used as a specific technical specification. The basic test data is for reference only for the performance of this product.